our core components

are working assembly plants

clear criteria for long lasting partners

main criteria for

assembly plan selection

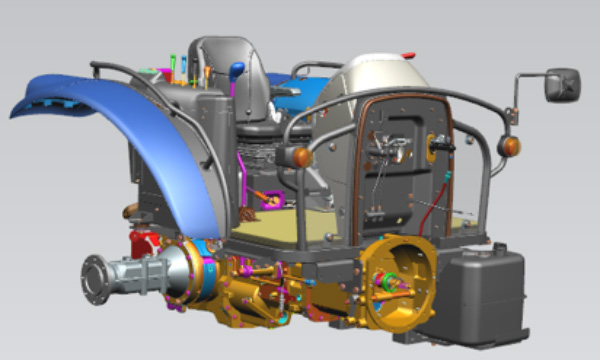

The industrial plants where the manufactured parts of tractors and agricultural implements will be assembled to obtain the finished product.

Green Imperative will offer all the necessary know-how for plants to operate efficiently and competitively, with the best market prices.

Working conditions

|

Item

|

Conditions

|

|---|---|

|

Working Days

|

250 days/year

|

|

Working hours

|

8 hours/day

|

|

Operating rate

|

70%

|

|

Tact Time

|

16.5 min/machine

|

|

Production Quantity

|

21 units/day

|

|

Yearly production

|

5,000 units/year

|

Model

|

Item

|

Conditions

|

|---|---|

|

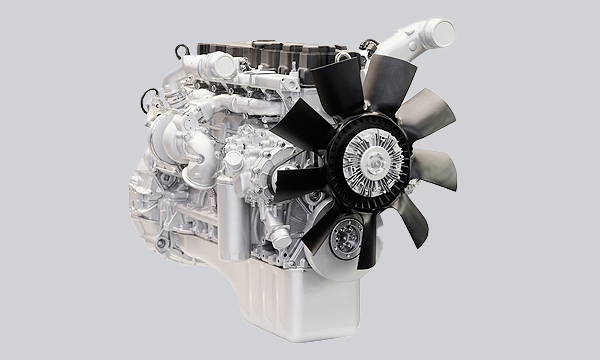

HP

|

80hp ~ 150hp

|

|

Basic model

|

80 / 105 / 150hp

|

Standard time

|

Item

|

Standard Time (minutes)

|

|---|---|

|

Sub-assembly

|

109.7

|

|

Assembly

|

279.6

|

|

Inspection

|

55.2

|

|

Total

|

444.5

|

Working conditions

|

Item

|

Blue

|

White

|

Total

|

|---|---|---|---|

|

Direct Main assembly

|

18

|

0

|

18

|

|

Direct Main sub-assembly

|

2

|

0

|

2

|

|

Direct Main inspection

|

2

|

0

|

2

|

|

Direct Sub Total

|

22

|

0

|

22

|

|

Indirect Material warehouse

|

2

|

0

|

2

|

|

Indirect Supply material

|

1

|

0

|

1

|

|

Indirect Production engineering

|

1

|

2

|

3

|

|

Indirect Production Plan

|

0

|

1

|

1

|

|

Indirect Maintenance

|

1

|

0

|

1

|

|

Indirect Shipment

|

1

|

0

|

1

|

|

Indirect Supervisor

|

1

|

1

|

2

|

|

Indirect Sub-total

|

7

|

4

|

11

|

|

Production Total

|

29

|

4

|

33

|

|

Quality IQC

|

1

|

1

|

2

|

|

Quality OQC

|

1

|

1

|

2

|

|

Quality Sub-total

|

2

|

2

|

4

|

|

Purchase Import

|

0

|

2

|

2

|

|

Purchase Local Part

|

0

|

3

|

3

|

|

Purchase Sub-total

|

0

|

5

|

5

|

|

CS Warehouse

|

2

|

0

|

2

|

|

Order Planning

|

0

|

1

|

1

|

|

CS SVC / Training

|

4

|

2

|

6

|

|

CS Sub-total

|

6

|

3

|

9

|

|

Design

|

0

|

0

|

0

|

|

Total

|

37

|

14

|

51

|

Development stages of Green Imperative Project

Cost & Gross Profit Margin (GPM) - Comparison

CKD

3rd level

Completely Knocked Down Plus

CKD with suppliers from different sources (includes local suppliers).

CKD

2nd level

Completely Knocked Down

Assembly of at least 40% of a CBU.

CKD

1st level

Knocked Down

Finished products “in operation”, subsequently disassembled into a very limited number of parts.

* Green Imperative Project makes use of CKD (see green boxes above).

** CKD Plus: Tires, battery, seats, headlight etc.

*** Responsibility of the Assembly Plant: Maintain stock of parts in slow and fast movement, after sales, training and tractor test.